Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

How Does Turning Lathe Precision Affect Product Consistency and Quality?

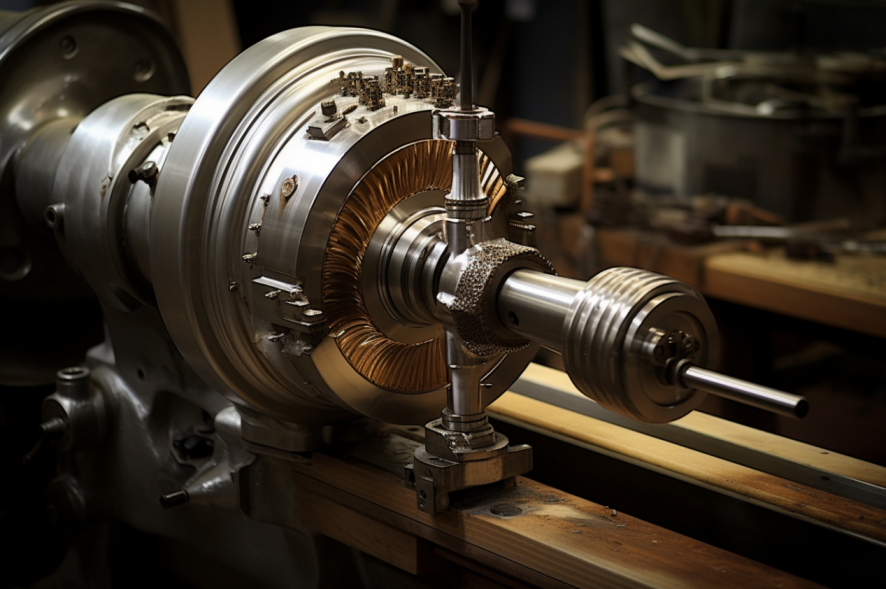

A turning lathe is a machine tool that spins a workpiece on its axis while a cutting tool moves linearly to shape the material. It plays a crucial role in manufacturing by enabling precise and efficient shaping of cylindrical components. Turning lathes offer a range of advantages, such as precision, versatility, and efficiency, making them essential tools in industries that https://www.louis-mct.com/products/.

Advantages of Turning Lathe Services

1.1 Precision

Turning lathes provide unparalleled precision, allowing manufacturers to produce components with tight tolerances and complex geometries. This precision is vital for industries like medical, where accuracy is crucial.

1.2 Versatility

Lathes can work with a variety of materials, including metals, plastics, and composites. This versatility makes them suitable for producing a wide range of products, from small electronic components to large industrial parts.

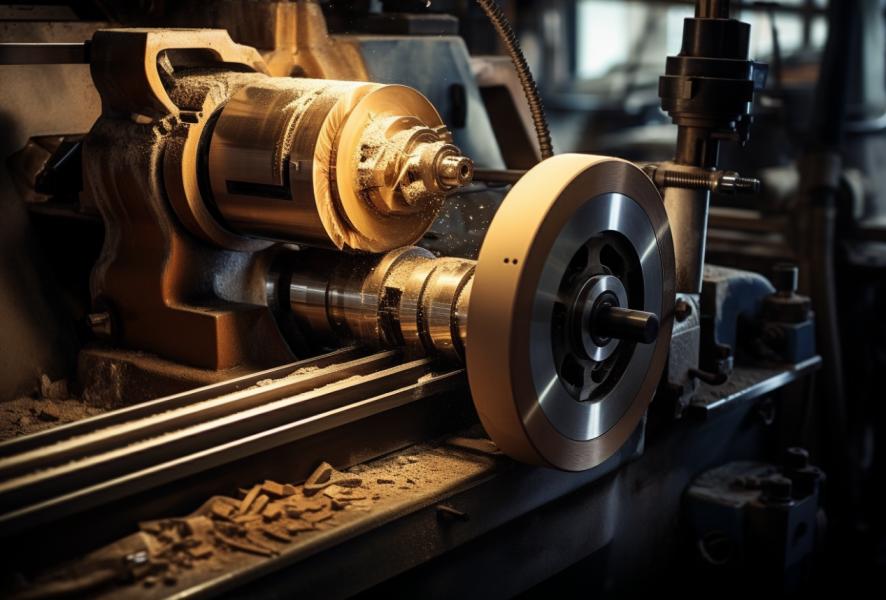

1.3 Efficiency

Turning lathes operate quickly and efficiently, enabling manufacturers to produce large quantities of parts in a short time. This efficiency is beneficial for industries with high production demands, such as automotive and electronics.

1.4 Electronic Product Accessories

Turning lathes play a significant role in the production of electronic product accessories. These machines are used to create small, precise components that are integral to electronic devices.

Producing Electronic Connectors

2.1 Precision Components

Turning lathes are ideal for manufacturing small, precise components like electronic connectors. These parts must fit perfectly to ensure proper electrical connections and functionality.

2.2 Material Selection

Lathes can work with a range of materials, including metals like copper and brass, which are commonly used in electronic connectors. The ability to work with different materials allows for flexibility in design and application.

2.3 Consistent Quality

The precision and repeatability of turning lathes ensure that electronic connectors meet strict quality standards, providing reliable performance in electronic devices.

Creating Sockets and Pins

3.1 Customization

Turning lathes can produce customized sockets and pins to match specific electronic components. This customization is crucial for devices with unique requirements.

3.2 Mass Production

Lathes are capable of high-volume production, allowing manufacturers to produce large quantities of sockets and pins efficiently. This is particularly beneficial for consumer electronics.

3.3 Durability and Reliability

By using high-quality materials and precise manufacturing processes, turning lathes produce durable and reliable sockets and pins that can withstand repeated use.

3.4 Machining Services

Turning lathes contribute to various machining services, including prototyping, production, and custom parts. These services are essential for industries like aerospace, automotive, and medical.

Prototyping with Turning Lathes

4.1 Rapid Prototyping

Turning lathes enable manufacturers to quickly produce prototypes for testing and validation. This rapid prototyping helps speed up product development and reduce time-to-market.

4.2 Design Flexibility

Lathes allow for easy adjustments and modifications during the prototyping phase, enabling manufacturers to fine-tune designs for optimal performance.

4.3 Material Variety

Turning lathes work with various materials, providing manufacturers with the flexibility to test different options during prototyping.

Production of Custom Parts

5.1 Tailored Manufacturing

Turning lathes can produce custom parts tailored to specific industry needs. This is especially important in sectors like aerospace and medical, where unique components are required.

5.2 High-Volume Production

Lathes can handle high-volume production runs while maintaining precision and quality, ensuring consistent parts for large-scale manufacturing.

5.3 Cost-Effective

The efficiency and precision of turning lathes contribute to cost-effective production, making them a preferred choice for custom parts manufacturing.

Louis Machine: Your Turning Lathe Service Provider

When it comes to turning lathe services, Louis Machine is a trusted provider with a reputation for delivering high-quality results. They offer a range of services, including prototyping, production, and custom parts, to cater to various industries.

6.1 Expertise and Experience

Louis Machine’s team of skilled technicians and engineers bring years of experience to every project, ensuring precision and quality in every component.

6.2 State-of-the-Art Equipment

Equipped with advanced turning lathes, Louis Machine can handle a variety of materials and complexities, providing tailored solutions to meet customer needs.

6.3 Commitment to Excellence

With a focus on excellence and customer satisfaction, Louis Machine strives to deliver top-notch turning lathe services that exceed expectations.

Manufacturing Mold Hardware with Turning Lathes

7.1 Precision Manufacturing

Turning lathes offer the precision required to manufacture mold hardware with tight tolerances. This precision ensures that components fit together perfectly, allowing for consistent and quality production.

7.2 High-Quality Surface Finish

A smooth surface finish on mold hardware is essential to prevent defects in the final product. Turning lathes can achieve exceptional surface finishes, enhancing the quality of the mold and the parts it produces.

7.3 Rapid Production for Mold Makers

Turning lathes enables rapid production of mold hardware, helping mold makers meet tight deadlines and customer demands. The speed and efficiency of turning lathes allow for quick turnaround times and high-quality output.

7.4 Quality Assurance and Inspection

Quality assurance is a critical aspect of turning lathe services to ensure that turned parts meet customer specifications and industry standards. Proper inspection and verification methods are essential for maintaining high-quality production.

Methods and Tools for Inspection

Turning lathe services use various tools and methods for inspecting turned parts, such as:

1. Micrometers and calipers: These tools measure dimensions accurately to ensure parts meet specified tolerances.

2. Optical comparators: These devices compare turned parts with design blueprints to verify shape and size.

3. Coordinate measuring machines (CMM): These machines provide precise measurements and detailed inspection of complex parts.

Best Practices for Quality Assurance

Best practices for ensuring quality in turning lathe services include:

1. Regular calibration: Keeping measurement tools calibrated ensures accurate and reliable results.

2. In-process inspection: Checking parts during production helps catch potential issues early and prevent defects.

3. Documentation and traceability: Keeping records of inspections and production batches allows for easy traceability and accountability.

9.1 Customization and Scalability

Turning lathes offer the ability to produce custom parts tailored to client needs and provide scalability for small-batch to large-scale production runs. These capabilities benefit a variety of industries.

9.2 Custom Parts for Client Needs

Turning lathes can produce custom parts based on specific client requirements. This flexibility allows manufacturers to create unique components for specialized applications in industries such as aerospace, automotive, and medical.

9.3 Scalability from Small to Large Production Runs

Turning lathe services can adapt to different production volumes, offering both small-batch and large-scale production runs. This scalability is advantageous for businesses with varying production needs and timelines.

Louis Machine: A Leader in Turning Lathe Services

Louis Machine is a trusted provider of turning lathe services, known for its commitment to quality, precision, and customer satisfaction. With state-of-the-art equipment and a team of skilled professionals, Louis Machine offers a wide range of services to meet diverse industry needs.

10.1 Expertise in Mold Hardware

Louis Machine has extensive experience in manufacturing mold hardware, including cores, cavities, and inserts. Their precision and quality assurance processes ensure high-quality mold components for consistent production.

10.2 Customization and Scalability

Louis Machine excels in providing custom parts tailored to client needs and can scale services to accommodate production runs of any size. This flexibility allows them to serve a wide range of industries.

10.3 Dedication to Quality

With a strong focus on quality assurance and inspection, Louis Machine ensures that every turned part meets or exceeds customer specifications and industry standards.

Conclusion

In conclusion, turning lathe services play a vital role in manufacturing across various industries. Providers like Louis Machine offer expertise, state-of-the-art equipment, and a commitment to excellence, ensuring high-quality results for their clients.