Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Cost-Effective: Professional Machining of Metal Hardware Parts Explained

Captivating the Reader’s Attention

Have you ever wondered how the smallest components can make or break an entire assembly? Consider the intricate world of metal hardware parts, where precision is paramount. From the bolts that hold structures together to the nuts and washers that ensure stability, these components are the unsung heroes of manufacturing. In a world increasingly driven by technology and innovation, the importance of professional machining of metal hardware parts cannot be overstated.

Cost-Effective Solutions: Professional Machining of Metal Hardware Parts Explained

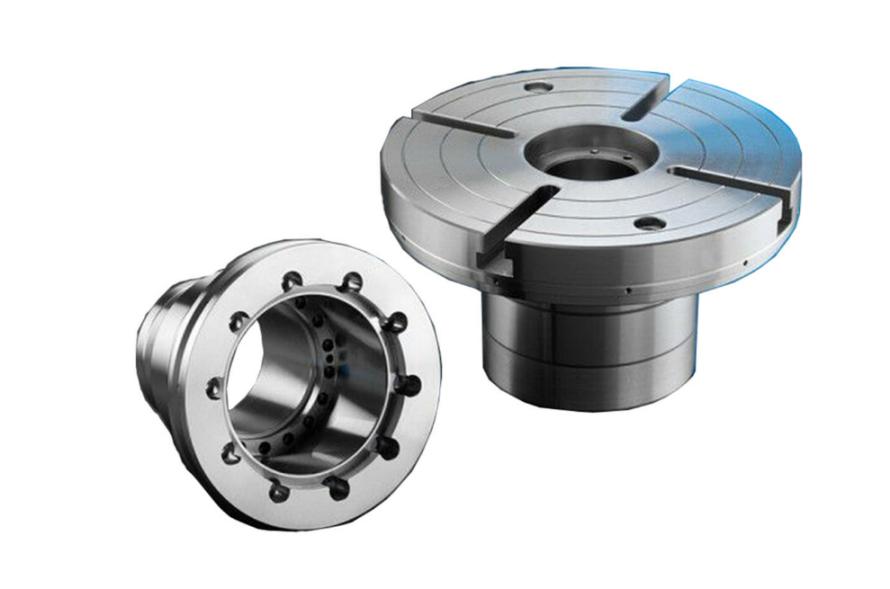

Professional machining of metal hardware parts refers to the process of shaping and finishing metal components using advanced machinery and techniques. This process ensures that the final products meet stringent quality standards, allowing manufacturers to rely on them for critical applications.

Understanding the Process

The machining process typically involves several stages, including cutting, grinding, and finishing. These stages are executed using various machines, such as CNC lathes and milling machines, which allow for high precision and efficiency. For example, a CNC lathe can perform turning operations with an accuracy of +/- 0.003mm, ensuring that each part fits perfectly in its intended assembly.

Benefits of Professional Machining

One of the key advantages of opting for professional machining services is cost-effectiveness. While initial costs might seem higher than DIY solutions, the long-term savings are significant. High-quality machined parts reduce the risk of failure, which can lead to costly downtimes and repairs. Additionally, professional services often provide bulk production options, further driving down the cost per unit.

Quality Assurance

Quality control is a critical aspect of professional machining. Suppliers like Louis Machine implement stringent quality control procedures to guarantee that raw materials meet high standards. Every product undergoes rigorous testing to ensure durability and reliability, thus reinforcing the idea that investing in professional machining is a smart financial decision.

Benefits of Choosing Professional Machining of Metal Hardware Parts for Your Business

The benefits of professional machining extend beyond cost-effectiveness. Choosing the right supplier can profoundly impact your business’s efficiency and product quality.

Reliability and Durability

When businesses invest in professional machining, they receive components that are not only precisely manufactured but also built to last. Using high-quality materials ensures that products like bolts, nuts, and washers can withstand the rigors of their intended applications. This reliability is crucial, especially in industries such as aerospace and automotive, where component failure can have dire consequences.

Enhanced Customization

Professional machining services offer a level of customization that is hard to achieve through conventional methods. Businesses can request parts with specific dimensions, materials, and finishes tailored to their needs. For instance, a game console handle mold can be processed through grinding, CNC milling, and discharge processing EDM to achieve the desired specifications.

Speedy Turnaround Times

In today’s fast-paced market, speed is often as crucial as quality. Professional machining companies understand this need and leverage their technology to offer quick turnaround times. With automated CNC machines, mass production of parts can occur rapidly without sacrificing accuracy, making it easier for businesses to meet tight deadlines.

A Deep Dive into Professional Machining of Metal Hardware Parts: Techniques and Tools

Understanding the techniques and tools used in professional machining is vital for appreciating its complexity and value.

Advanced Machining Techniques

Several advanced techniques are utilized in professional machining, including CNC milling, turning, and EDM (Electrical Discharge Machining). Each method offers unique advantages that cater to different needs. For instance, CNC milling machines excel in creating complex 3D shapes, while EDM is renowned for its ability to produce intricate features with extreme accuracy.

Tools of the Trade

The tools used in professional machining play a significant role in determining the quality of the final product. For example, discharge processing EDM can achieve an accuracy of +/- 0.003mm, making it ideal for applications requiring precise dimensions. The use of high-quality stainless steel, copper, and aluminum in manufacturing further ensures the durability of the components.

The Role of Technology

Technological advancements have revolutionized the machining process, enabling faster production with enhanced precision. Companies like Louis Machine leverage state-of-the-art equipment, such as automatic CNC lathes and composite machine tools, to produce high-quality metal parts. These innovations not only improve efficiency but also expand the capabilities of what can be achieved in machining.

The Future of Professional Machining of Metal Hardware Parts: Trends to Watch

As industries continue to evolve, so too will the landscape of professional machining. Staying informed about emerging trends is essential for businesses looking to maintain a competitive edge.

Increasing Automation

Automation is set to play a significant role in the future of machining. With advancements in robotics and AI, manufacturers can expect even greater efficiencies and reduced human error. Automated CNC machines can perform multiple operations simultaneously, streamlining production and reducing costs.

Sustainable Practices

Sustainability is becoming a critical focus for manufacturers. As consumers demand more environmentally friendly products, the machining industry is adapting by adopting sustainable practices. This includes using recyclable materials and implementing energy-efficient manufacturing processes, which not only benefit the environment but also appeal to eco-conscious consumers.

Customization and Additive Manufacturing

The demand for customization will continue to rise, leading to an increase in additive manufacturing techniques. These methods allow for the creation of complex geometries that traditional machining cannot easily achieve. Businesses will benefit from this trend by being able to offer highly specialized products that meet specific customer needs.

Conclusion

In conclusion, professional machining of metal hardware parts is an indispensable facet of modern manufacturing, playing a crucial role in ensuring the quality and reliability of various products. By understanding the intricacies of its processes, benefits, and emerging trends, businesses can make informed decisions that significantly enhance their operational efficiency and competitiveness in the market. Partnering with reliable suppliers like Louis Machine allows companies to access high-quality, precisely manufactured components tailored to their specific needs. This collaboration not only fosters innovation but also contributes to long-term success and sustainability. Moreover, as industries evolve, the commitment to professional machining reflects a dedication to excellence and precision, setting the stage for future advancements in manufacturing technology. Ultimately, investing in professional machining is not merely a choice—it’s a strategic decision that positions businesses for growth and resilience in an increasingly demanding landscape.