Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

How Does Precision 0.003mm Accuracy Processing Benefit Various Industries?

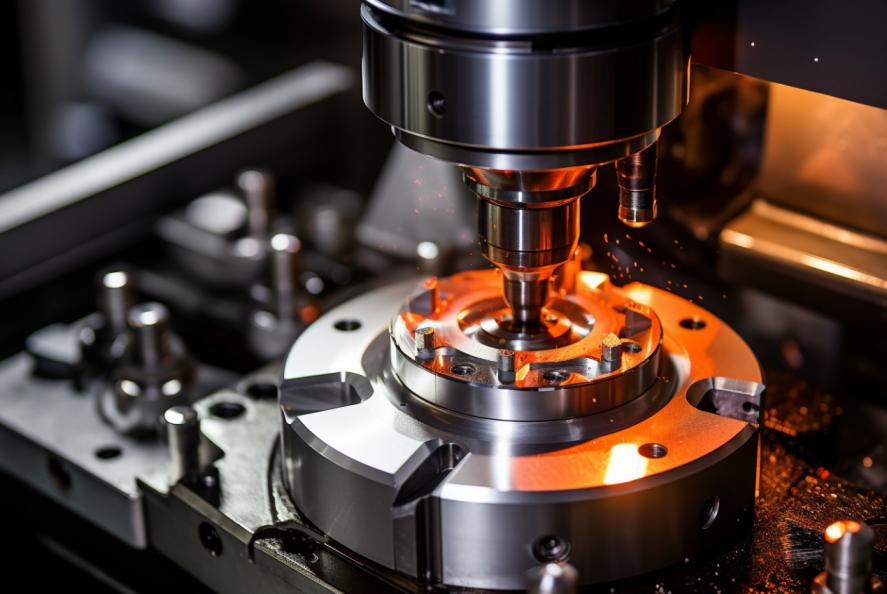

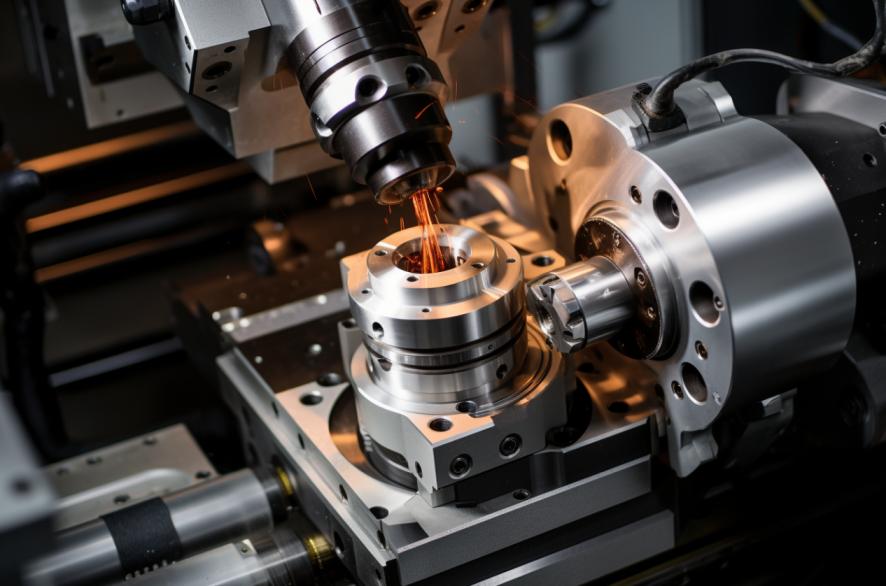

Precision is key when it comes to manufacturing products for the automobile accessory, electronic consumer, and precision hardware industries. Louis Machine, a leading provider of 0.003mm accuracy machining services, excels in delivering high-quality products with exact specifications. With a focus on precision mold design and manufacturing, advanced plastic injection molding, and precision metal hardware parts processing, Louis Machine is a trusted partner for manufacturers seeking exceptional results.

Precision Mold Design and Manufacturing for Automobile Accessory Manufacturers

1.1 Understanding the Importance

Precision molds play a crucial role in creating intricate automobile accessories that meet the industry’s high-quality standards. These molds ensure that every part is accurately crafted with meticulous detail, resulting in components that fit perfectly and function seamlessly.

a. Creating Detailed Designs: Louis Machine’s team of experts designs molds with exceptional precision, ensuring every detail is considered for optimal performance and aesthetics.

b. High-Quality Finishes: Precision molds help produce accessories with superior finishes, adding value and appeal to automobile products.

c. Maintaining Stringent Standards: By focusing on precision and quality, Louis Machine ensures that each accessory meets stringent industry standards for safety and functionality.

1.2 Louis Machine’s Approach

Louis Machine’s experienced team combines cutting-edge technology with innovative design to produce molds that guarantee exceptional accuracy and performance.

a. Tailored Solutions: Louis Machine offers custom design consultations to create molds tailored to your specific needs and requirements.

b. Rapid Prototyping: Speed up your production process with rapid prototyping services, enabling you to test and refine designs quickly and efficiently.

c. Efficient Mold Production: Louis Machine’s advanced manufacturing facilities ensure the timely production of high-quality molds for your automobile accessories.

1.3 Advantages of Choosing Louis Machine

Partnering with Louis Machine offers a range of benefits, including:

a. Comprehensive Solutions: Enjoy a one-stop service from design to manufacturing, saving you time and effort.

b. Precision and Accuracy: Count on Louis Machine’s precise processes to produce molds that meet your exact specifications.

c. Reliability and Quality: With a focus on quality control and customer satisfaction, you can trust Louis Machine to deliver exceptional results.

Advanced Plastic Injection Molding for Electronic Consumer Manufacturers

2.1 The Role of Plastic Injection Molding

Precision in plastic injection molding is essential for creating reliable and efficient components in electronic devices and gadgets.

a. Consistency and Reliability: Precise molding ensures that every part functions correctly and consistently, contributing to the overall quality of electronic products.

b. Enhanced Performance: Well-designed plastic components can improve device performance and user experience.

c. Aesthetic Appeal: High-quality plastic parts with smooth finishes add to the visual appeal of consumer electronics.

2.2 Louis Machine’s Capabilities

Louis Machine leverages state-of-the-art injection molding processes to produce parts that meet the demanding standards of the electronic consumer industry.

a. Innovative Techniques: Advanced techniques allow Louis Machine to produce complex shapes and designs with ease.

b. Material Selection: Access to a wide range of materials ensures that each part is crafted for optimal performance and durability.

c. Testing and Quality Assurance: Louis Machine rigorously tests every part to guarantee consistency, accuracy, and quality.

2.3 Why Choose Louis Machine

Louis Machine’s dedication to excellence and quality sets it apart from the competition.

a. Expertise and Experience: With years of experience in injection molding, Louis Machine offers unparalleled expertise in delivering exceptional results.

b. Attention to Detail: Every aspect of the process is carefully managed to ensure precision and quality.

c. Commitment to Customers: Louis Machine strives to exceed customer expectations with every project.

Precision Metal Hardware Parts Processing for Precision Hardware Manufacturers

3.1 The Need for Precision in Metal Parts

Exact metal hardware parts are crucial in industries such as construction, engineering, and more. Precision in these parts ensures safety, durability, and efficiency.

a. Dependable Performance: Precision metal parts function reliably, contributing to the success of various applications.

b. Customized Solutions: Tailored processing methods ensure each part meets specific industry needs and standards.

c. Enhanced Product Longevity: Accurate machining leads to parts that last longer and perform better.

3.2 Louis Machine’s Expertise

Louis Machine’s precision machining processes deliver tight tolerances and flawless finishes for metal parts.

a. Advanced Machinery: State-of-the-art equipment enables Louis Machine to produce intricate and precise metal components.

b. Complex Project Handling: Louis Machine can handle projects of any complexity, providing efficient solutions for your manufacturing needs.

c. Focus on Quality: Quality control measures ensure that every part meets the highest standards of excellence.

3.3 Benefits of Collaborating with Louis Machine

Working with Louis Machine offers many advantages:

a. Rapid Turnaround Times: Benefit from fast production times without compromising on quality.

b. Expert Collaboration: Louis Machine’s team of experts works closely with clients to understand their needs and deliver optimal results.

c. Commitment to Excellence: Louis Machine’s dedication to quality and customer satisfaction ensures a successful partnership every time.

Comprehensive Automotive Parts Manufacturing for Automotive Manufacturers

4.1 Critical Automotive Parts Manufacturing

Producing automotive parts with extreme precision is challenging due to the high standards of safety, efficiency, and quality expected in the industry. Louis Machine understands these challenges and meets them with cutting-edge technology and expertise.

a. Exact Specifications: Precision is essential for automotive parts to function correctly and meet industry regulations.

b. Variety of Components: From engine components to interior fittings, Louis Machine can manufacture a wide range of automotive parts with exceptional accuracy.

c. Focus on Performance: High-quality automotive parts contribute to the overall performance and safety of vehicles.

4.2 Louis Machine’s One-Stop Solutions

Louis Machine offers comprehensive solutions for automotive manufacturers, simplifying the production process and delivering outstanding results.

a. Advanced Manufacturing: State-of-the-art facilities allow Louis Machine to produce parts with exceptional precision.

b. Customization and Flexibility: Whether it’s prototyping or mass production, Louis Machine tailors its services to meet your specific needs.

c. Quality Assurance: Rigorous quality control measures ensure that each part meets the highest standards of excellence.

4.3 Why Trust Louis Machine

Partnering with Louis Machine comes with a host of benefits that set it apart from the competition.

a. Competitive Pricing: Louis Machine provides cost-effective solutions without compromising on quality.

b. Large-Scale Production: Louis Machine can handle projects of any scale, from small batches to large production runs.

c. Customer-Centric Approach: By working closely with clients, Louis Machine ensures that each project aligns with your unique requirements and expectations.

Integrated Design and Manufacturing Solutions

5.1 The Importance of Integrated Solutions

Having a single source for both design and manufacturing services can offer significant advantages for manufacturers. Louis Machine’s integrated approach streamlines the production process, saving time and reducing costs.

a. Efficiency and Speed: Integrated solutions allow for seamless transitions between design and manufacturing, expediting the entire production process.

b. Consistent Quality: By overseeing every stage of production, Louis Machine ensures consistent quality throughout the project.

c. Reduced Complexity: Streamlining the process minimizes the risk of errors and miscommunication between different stages of production.

5.2 Louis Machine’s Approach

Louis Machine’s integrated approach combines innovative design with precision manufacturing to deliver top-notch results.

a. Expert Collaboration: Louis Machine’s team of experts collaborates with clients to understand their vision and provide tailored solutions.

b. Advanced Technology: Cutting-edge technology enables Louis Machine to offer efficient and precise manufacturing services.

c. Customization: Louis Machine can customize its services to suit the unique needs of each industry and project.

5.3 Advantages for Various Industries

Louis Machine’s integrated solutions offer benefits across multiple industries, including:

a. Automobile Accessory Manufacturers: Streamlined processes ensure that accessories are designed and manufactured to the highest standards.

b. Electronic Consumer Manufacturers: Consistent quality and precision are crucial for producing reliable electronic components.

c. Precision Hardware Manufacturers: Efficient design and manufacturing lead to accurate and high-quality hardware parts.

Unparalleled Customer Support and Quality Assurance

6.1 Commitment to Customer Satisfaction

At Louis Machine, customer satisfaction is a top priority. The company goes above and beyond to ensure that clients are pleased with the services provided and continue to build long-term partnerships.

a. Dedicated Support: Louis Machine’s team is always available to address any questions or concerns throughout the production process.

b. Transparent Communication: Clear and open communication ensures that clients are informed at every stage of their project.

c. Tailored Solutions: Louis Machine works closely with clients to provide solutions that match their unique requirements and goals.

6.2 Our Quality Assurance Process

Louis Machine’s quality assurance process is designed to deliver superior products that meet or exceed industry standards.

a. Rigorous Testing: Every part undergoes thorough testing and inspection to ensure it meets exact specifications.

b. Attention to Detail: From material selection to final product inspection, Louis Machine maintains high standards of precision.

c. Continuous Improvement: Louis Machine constantly evaluates and refines its processes to enhance quality and efficiency.

6.3 Building Trust with Louis Machine

Louis Machine’s dedication to precision, transparency, and collaboration sets it apart in the industry.

a. Commitment to Excellence: Louis Machine strives for excellence in every project, ensuring outstanding results for clients.

b. Reliability and Dependability: You can trust Louis Machine to deliver on its promises and exceed your expectations.

c. Long-Term Partnerships: By focusing on building lasting relationships, Louis Machine becomes a trusted partner for your precision machining needs.

Conclusion

In summary, Louis Machine provides exceptional 0.003mm accuracy machining services, making it the ideal partner for manufacturers in the automobile accessory, electronic consumer, and precision hardware industries. With a commitment to quality, precision, and customer satisfaction, Louis Machine stands out as a leader in precision machining services. Contact Louis Machine today to experience the difference firsthand.