Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

Louis Machine: Pioneering Precision Medical Device Component Manufacturer

The medical device manufacturing industry stands as a cornerstone in modern healthcare, ensuring clinicians have access to the tools necessary for diagnosis, treatment, and patient care. At the heart of this intricate ecosystem is component manufacturing, a realm where precision and reliability are paramount.

Louis Machine, a name synonymous with excellence in this niche. As a stalwart in the domain, Louis Machine has etched its position as a leading medical device component manufacturer, producing components that not only meet but often exceed industry standards. Our reputation for quality and innovation has solidified our status as a key player, driving advancements and setting benchmarks for others to follow.

Who are we?

Overview

Founded in 2011 in Shenzhen, Louis Machine is a professional machining company with a wide range of capabilities, including precision mold design, plastic injection molding, metal hardware parts processing, and automotive parts manufacturing. Our team comprises experienced technical experts and skilled management personnel, offering comprehensive solutions for design, manufacturing, injection molding, die-casting, and mass parts processing.

Journey into Custom Machinery and Automotive Excellence

In the 2010s, we expanded our horizons into custom machinery and automation solutions, fueling our growth. By 2015, we had earned a reputation for innovation and product reliability, leading to the establishment of our automobile metal product factory.

A major milestone in our journey came in 2022 when our lab received recognition from national institutions. Our proprietary instant quoting system ensures quick and accurate quotes, and our streamlined production guarantees timely delivery of custom parts, all while maintaining a strong focus on quality. We proudly hold an ISO 9001:2015 certification to ensure top-notch quality throughout our processes.

Cutting-Edge Equipment and Expertise

Today, our state-of-the-art equipment, sourced from Germany, Switzerland, and Japan, includes precision CNC machines. With decades of experience in design and manufacturing, our engineering team excels in process analysis and solutions. Our skilled processing team achieves sub-micron-level grinding accuracy, while our CNC processing center delivers precision to within +/- 0.002mm. Our wire cutting and EDM processes maintain accuracies of +/- 0.001mm and +/- 0.003mm, respectively, exemplifying our commitment to excellence.

Core Competencies

Louis Machine excels in medical component manufacturing, leveraging a rich tapestry of expertise, cutting-edge technologies, and meticulous methodologies.

- Advanced CNC Machining

Louis Machine’s state-of-the-art CNC machines from Germany, Switzerland, and Japan ensure precision to within +/- 0.002mm, a critical requirement for medical components.

- Materials Mastery

The company’s profound knowledge of various materials, including medical-grade plastics and metals, enables them to select the ideal material for each application, ensuring safety and durability.

- Engineering Prowess

With decades of experience, our engineering team excels in process analysis and solutions, tailoring production methods to meet the unique demands of medical component manufacturing.

- Tight Tolerances

Achieving sub-micron-level grinding accuracy is a testament to our commitment to precision, vital for medical devices where even slight variations can be critical.

- Electrical Discharge Machining (EDM)

Louis Machine’s EDM processes maintain accuracies of +/- 0.001mm (wire cutting) and +/- 0.003mm (electric spark EDM), guaranteeing the finest detail and reliability.

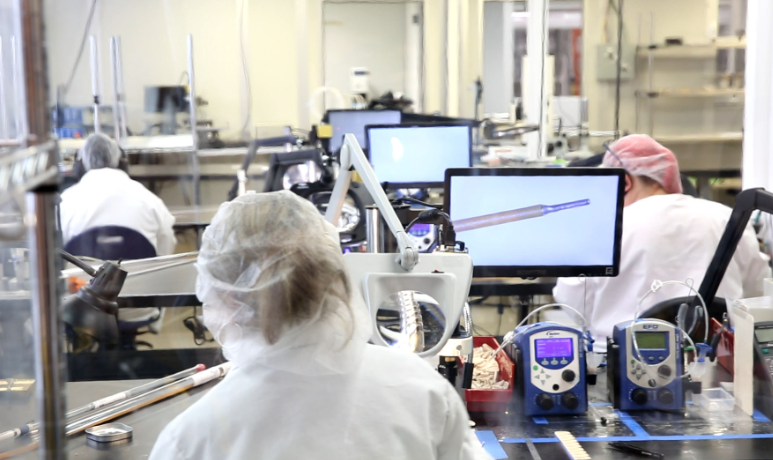

- Cleanroom Facilities

For medical applications, cleanliness is paramount. Louis Machine’s cleanroom facilities ensure that components meet the strictest hygiene and contamination control standards.

- Quality Assurance

Our ISO 9001:2015 certification underscores their unwavering dedication to producing high-quality medical components that meet regulatory and industry standards.

Importance of Precision in Medical Components

Precision in medical components is paramount for several critical reasons:

Patient Safety

In the medical field, even the smallest discrepancy can have life-threatening consequences. Precision ensures that medical devices perform as intended, reducing the risk of errors, complications, and harm to patients.

Consistency

Precise components guarantee uniformity in device performance. This is crucial for medications, diagnostics, and surgical instruments, where consistency in dosage, measurement, or cutting is essential for accurate diagnoses and treatments.

Reliability

Medical devices need to work flawlessly in high-stress situations. Precision reduces the likelihood of device failure, ensuring that they can be trusted when needed most, such as during surgeries or emergency situations.

Minimized Tissue Damage

Surgical tools and implants with precise dimensions minimize tissue trauma during procedures, leading to faster recoveries and reduced patient discomfort.

Regulatory Compliance

Medical components must adhere to strict regulatory standards. Precision is a fundamental requirement to meet these standards and obtain necessary approvals, ensuring the legality and safety of medical devices.

Cost Efficiency

Precision manufacturing can reduce waste and the need for rework, ultimately leading to cost savings in the production of medical components.

Innovation at Louis Machine

Innovation is the driving force at Louis Machine, at the heart of our operations, propelling us to continuously explore new horizons in research and development (R&D). Our R&D philosophy is distinguished by the following principles:

Interdisciplinary Collaboration

We actively encourage collaboration among our engineers, technicians, and designers, facilitating the exchange of ideas and expertise across diverse domains. This synergy empowers us to craft comprehensive solutions for intricate manufacturing challenges.

Pioneering Technologies

We make substantial investments in state-of-the-art technologies and equipment, meticulously sourced from global industry leaders. Our unwavering commitment to remaining at the vanguard of technological advancements empowers us to provide high-precision components and pioneering solutions.

Tailored Solutions

Louis Machine embraces a personalized approach to R&D, crafting solutions tailored to the distinctive requirements of each project. We closely engage with our clients to grasp their precise needs, and when necessary, we innovate bespoke manufacturing techniques to meet those needs.

Future Directions and Commitment to Excellence

Louis Machine is dedicated to pushing the boundaries of precision and innovation in the manufacturing of medical device components. Our upcoming endeavors involve incorporating state-of-the-art materials and sustainable methods, elevating both product quality and environmental stewardship.

We aspire to be at the forefront of advancing next-gen medical devices, emphasizing miniaturization, connectivity, and user-centric designs. Our vision revolves around a future where medical devices aren’t just precise but also incredibly versatile and user-friendly, setting new benchmarks for excellence in healthcare.

CONCLUSION

Louis Machine stands as a trailblazer medical device component manufacturer, consistently delivering precision components crucial for healthcare advancements. Our commitment to quality and innovation has positioned us as a vital partner in medical technology, setting benchmarks for excellence and reliability.