Blog

We regularly update articles related to the prototyping and manufacturing industry. You’re welcome to check our previous blogs and subscribe to our newsletter.

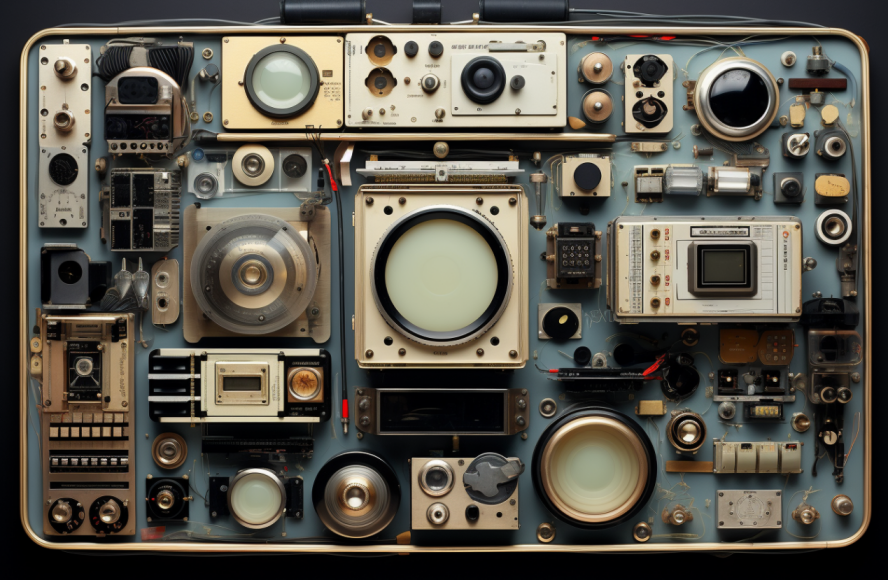

2024 Best Inspection Equipment in Latest Modern Manufacturing

In the era of high precision manufacturing, ensuring the quality and accuracy of products is paramount. Advanced technology and management concepts are essential for producing high-quality products, particularly in industries such as consumer electronics, automotive, and communication technology. Louis Machine, a leading manufacturer located in Shenzhen, China, excels in providing precision plastic products, automotive parts, and a range of other high-precision components. This article delves into the production process of different industries and how Louis Machine uses the most precise inspection equipment to guarantee product quality.

Industry Status and Needs

1.1 Consumer Electronics

The consumer electronics industry is rapidly evolving, with constant innovation driving the need for precise and reliable components. Manufacturers must produce parts with exceptional accuracy to meet the stringent demands of smart devices, wearable technology, and electronic communication devices. High-precision molds and plastic parts are essential for these products, necessitating the use of advanced inspection equipment to ensure quality and performance.

1.2 Automotive Industry

In the automotive sector, the focus on safety, fuel efficiency, and performance has led to an increased demand for precision hardware parts and assemblies. Components such as engine shells, light lamp covers, and interior panels must meet rigorous quality standards. High precision and consistent performance are vital to the overall safety and reliability of vehicles, making the role of inspection equipment critical in this industry.

1.3 Communication Technology

The communication technology industry relies on precise components for efficient and reliable data transmission. From precision parts used in electronic communication devices to high-quality connector assemblies, manufacturers must adhere to tight tolerances and quality standards. Advanced inspection equipment ensures that these components meet the exacting demands of this industry.

Solutions Provided by Louis Machine

2.1 Advanced Inspection Techniques

Louis Machine employs the latest inspection technologies to guarantee the quality of its products across various industries. The company utilizes high-precision measuring machines and devices that can detect minute deviations from specified tolerances. This ensures that all parts conform to the stringent requirements of their respective industries.

2.2 Precision Control and Measurement

The highly trained technical team at Louis Machine is capable of achieving sub-micron level grinding accuracy. CNC processing centers maintain a tolerance of +/-0.002mm, while wire cutting (EDM) reaches an accuracy of +/-0.001mm. Electric spark EDM achieves a tolerance of +/-0.003mm, ensuring precision in every manufacturing process.

2.3 Comprehensive Quality Control System

Louis Machine has established a comprehensive quality control system, including a materials laboratory that is accredited by the national department (CNAS). All mold steels undergo strict testing, and reports are retained for at least two years. This rigorous approach to quality control ensures that products meet the highest standards of precision and reliability.

A Comprehensive Range of Inspection Equipment

Louis Machine offers a comprehensive range of inspection equipment designed to meet the diverse needs of various industries. From simple measurement tools to complex automated systems, Louis Machine has it all.

3.1 Precision Tools for Quality Control

Louis Machine provides precision tools such as calipers, micrometers, and gauges that enable businesses to maintain strict quality control standards. These tools are engineered for accuracy and durability, ensuring reliable performance even under demanding conditions.

3.2 Advanced Inspection Systems

In addition to basic tools, Louis Machine also offers advanced inspection systems such as coordinate measuring machines (CMMs), optical comparators, and non-destructive testing (NDT) equipment. These state-of-the-art systems provide accurate measurements and inspections for complex parts and assemblies.

Unmatched Expertise and Support

What sets Louis Machine apart from other suppliers is their dedication to providing unmatched expertise and support to their clients.

4.1 Knowledgeable Staff

Louis Machine’s team of experienced professionals is well-versed in the latest inspection technologies and can offer valuable guidance in selecting the right equipment for any application. They take the time to understand each client’s unique needs and provide personalized recommendations.

4.2 Comprehensive Training and Maintenance

Once clients have chosen their inspection equipment, Louis Machine ensures a smooth transition by offering comprehensive training on proper operation and maintenance. Their team is always available to answer any questions and provide ongoing support throughout the equipment’s lifespan.

Reliable and Timely Delivery

Louis Machine understands the importance of timely delivery when it comes to inspection equipment services. Their efficient logistics and supply chain management ensure that clients receive their equipment on time and in perfect condition.

5.1 Wide Distribution Network

Thanks to its extensive distribution network, Louis Machine can deliver inspection equipment to clients across the country. This wide reach allows them to serve businesses in various industries, regardless of their location.

5.2 Customizable Solutions

For clients with unique requirements, Louis Machine offers customizable solutions tailored to their specific needs. From specialized equipment to bespoke setups, they work closely with clients to deliver solutions that meet or exceed expectations.

Commitment to Innovation

Louis Machine is committed to staying at the forefront of inspection technology. They continually invest in research and development to bring the latest advancements to their clients.

6.1 Cutting-Edge Technologies

By partnering with leading manufacturers and research institutions, Louis Machine provides clients with access to cutting-edge technologies. This commitment to innovation ensures that clients always have the best tools and systems available for their inspection needs.

6.2 Ongoing Updates and Upgrades

Louis Machine doesn’t just provide the latest equipment; they also offer ongoing updates and upgrades to keep clients’ systems up to date. This proactive approach ensures that clients can maintain their competitive edge and achieve the highest quality standards.

Comprehensive Services and Manufacturing Capabilities

7.1 Mold Design and Production

Louis Machine provides a one-stop service in mold design and production, plastic injection, die casting, and hardware manufacturing. Specializing in auto parts and plastic product injection, precision parts, and mold production, the company boasts a large capacity and a team of well-trained engineers to meet client needs.

7.2 Fast Response and Efficient Communication

From the moment Louis Machine receives an email inquiry, their team is quick to respond and provide quotations within 24 hours. This efficiency reflects the company’s commitment to customer satisfaction and streamlined business processes.

7.3 OEM/ODM Services

Louis Machine offers OEM/ODM services to accommodate the unique needs of various customers. With full 2D and 3D mold design capabilities, clients receive personalized, tailored solutions for their specific projects.

Conclusion

Louis Machine stands out in the manufacturing industry due to its commitment to excellence and quality. By continuously introducing high-precision equipment, hiring senior engineers, and developing advanced technology and management concepts, the company provides customers with precision plastic products and other essential components across various industries.

Through its use of cutting-edge inspection equipment and adherence to strict quality control processes, Louis Machine guarantees that its products meet the highest standards of quality. This approach has allowed the company to build a reputation for excellence and reliability in the manufacturing of precision parts for the consumer electronics, automotive, and communication technology industries.